Pièces de coulée de die de magnésium de haute qualité avec différents traitements de surface

Informations de base

Modèle: Kenos-1001

Description du produit

| Product name | High quality magnesium die casting parts with different surface treatments | |||||

| Briefly Description | 1. Zinc is the main product material | |||||

| 2.10 year's experience in die casting field | ||||||

| 3.OEM and ODM service offered | ||||||

| 4. One stop service from die cast mould making to product casting | ||||||

| Mold type | Die casting mould | Usually packaging | Paper of Box | |||

| Manufacturer | Kenos Hardware Technology | Orginal place | Dongguan China | |||

| Supply capability | 50000PCS/WEEK | Terms of transport | by ship or express | |||

| About Our Mould : | ||||||

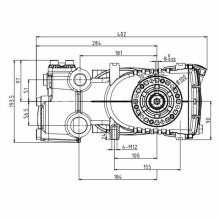

| 1)Mold type: die casting mold as customer's drawing or sample | ||||||

| 2)Mold tolerance:generally wirthin +/-0.03mm | ||||||

| 3)Mold size:either small or big are available according to product,generally length from 100mm to 500mm | ||||||

| 4)Mold making process:milling,grinding,wire cutting,CNC,EDM,etc | ||||||

| 5)Mold making equipment: | ||||||

| 1. eight sets of milling machine | ||||||

| 2.three sets of grinder | ||||||

| 3. two sets of wire cutting machine | ||||||

| 4. one set of CNC machine | ||||||

| 5. five sets of EDM machine | ||||||

| 6)Mould life:Over 1000,000 shots,lifetime free for maintaining the mould | ||||||

| 7)Drawing type:PDF,DWG,IGS,STP,STEP,PRT are all acceptable | ||||||

| About Our Product: | ||||||

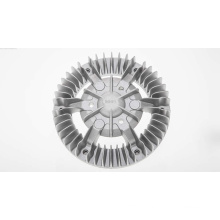

| 1)material type:magnesium alloy with SGS certification | ||||||

| 2)Product tolerance:according to customer's requirement and decided by the mold | ||||||

| 3)Main products:die casting parts,die casting accessories,die casting components, including phone shell,automotive parts,compouter parts,PC parts,bicycle parts,camera parts,housing,parts,gears,diy tools,optical components,engine components,pump components,furniture,fittings,etc | ||||||

| 4)Related industry:computer,cellphone,communication,LED,automotive,Camera,optical,etc | ||||||

| 5)Main process: Die casting,deburring,hole drilling,tapping,polishing,plating,inspecting,packaging | ||||||

| 6)Product making equipment: | ||||||

| 1. 2 sets of die casting machine (hot chamber) | ||||||

| 2. 8 sets of punch press | ||||||

| 3. 3 sets of hole-punching machine | ||||||

| 4. 15 sets of tapping machine | ||||||

| 5. 2 sets of CNC machine | ||||||

| 7)surface finish:Zinc plating,Chrome plating,Trivalent chrome plating,Powder coating,Painting,E-Coating.Phosphating,Anodizing,etc | ||||||

| Our main advantage: | ||||||

| 1)specialize in magnesium and zinc die casting for 10 years | ||||||

| 2)Green products with many international certification | ||||||

| 3)Good quality products with competitive price | ||||||

| 4)Best after-sale service | ||||||

| 5)One stop service to solve all of your problems | ||||||

| 6)Always on service for you during your working time | ||||||

| 7)Quotation will be sent within 24 hours any time | ||||||

| 8)Always on service for you during your working time | ||||||

| 9)Samples could be provided for customer's trail and test.Once not meet customer's need, | ||||||

| we will modisfy the mold until customer's satisfactory | ||||||

Mould Design

fraisage processing

EDM wire cutting

moule inspection

moule inspectionmoisissure salle

produit die casting processus :

zinc die casting

Degating

Deburring

forage et tapping

CNC produit Inspection :

salle d’Inspection 1

Inspection chambre paquet 2

:

Groupes de Produits : Alliage coulée sous pression

Premium Related Products

autres produits

Produits phares

Boîte de logement de moulage de précision en acier inoxydableLogement en zincLogement de flexionPièces de moulage en fonte ductile-coulée de sable vertCapuchon de filtre-commande numérique par ordinateur de coulée Ss316, coulée de cire perdueCorps de verrouillage automatique-Acier inoxydable Ss316 Coulée de cire perdueCoulée de précision SS (AISI304)Pièces de forgeage pour barre avant pivotante ferroviaireMoulage en fonte ductile du moyeu fabriqué à partir de la coulée de mousse perdueRaccords de tuyauterie en aluminium par gravitéBoîtier de machine à café expresso fabriqué par moulage mécanique sous pression avec une excellente finitionFabrication haute précision zamak moulage mécanique sous cas téléphone SamsungMoulage des composants de communication mécanique sous aluminium haute pressionfait sur commande aluminium, de zinc et de magnésium en alliage de moulage mécanique sous pressionPrecision Magneisum Die casting boîtiers de téléphoneFabrication de moule die casting magnésium en précision